Details

RENK AG’s beginnings go back to 1873, when Johann Julius Renk founded a small machining workshop for the mechanical production of gear wheels in Augsburg’s Lechviertel. In 1879, the young company moved to the Göggingen neighbourhood, where RENK’s headquarters are still located today. The company was converted into a joint-stock company in 1897, and RENK has been part of what is now the MAN Group since 1923.

RENK also became part of the Volkswagen Group when Volkswagen AG acquired a majority stake in MAN SE in 2011. Today, RENK has a global outlook as a leading supplier of high-quality drive technology for a wide range of applications. The company’s branches in Augsburg, Rheine, and Hanover are its major production locations.

RENK’s products and services are consistently tailored to the needs of our customers. Absolute precision, commitment, and speed are the basic prerequisites for efficiency and the capacity to act, especially in sensitive business areas. This commitment to the highest quality standards is what sets apart each and every subsidiary and company in the RENK Group around the world. Their flexibility, willingness to cooperate, and technical understanding enable them to communicate with customers and provide systems advice as partners. RENK has been defining standards and what is technically possible for many years in four strategic business units.

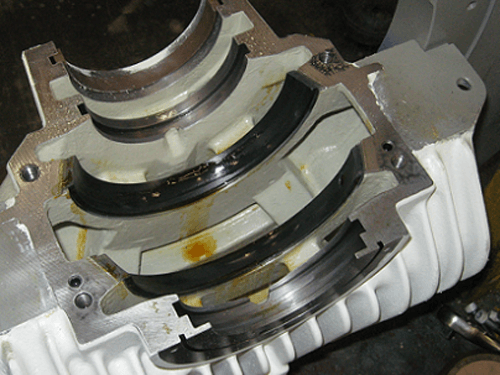

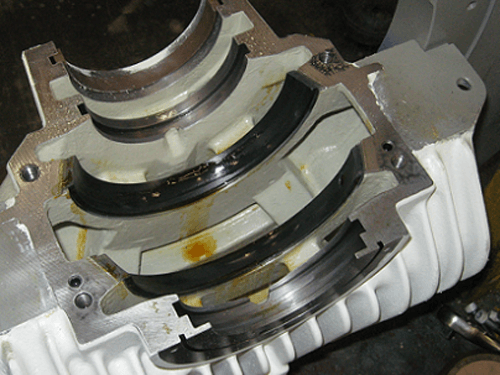

RENK slide bearings are manufactured by RENK AG Hannover Plant, in which the main types of bearings for motors are EF Series, EM Series, ER/EG Series and ZM Series.

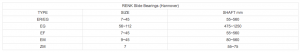

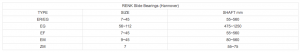

RENK Slide Bearings (Hannover)

Technical Data

Technical data

Design: EM bearing

Construction:

Finned middle flange bearing acc. to DIN 31694 / ISO 11687-3

Size:

9 … 28, for shafts Ø 80 … 355 mm

35 … 45, for shafts Ø 300 … 560 mm (600 mm, without axial component)

Lubrication:

Self-lubricating (loose oil ring, fixed oil ring) or external lubrication

Cooling system:

Natural cooling, water cooling, or external cooling

Bore design:

Various bore designs as required, e.g. cylindrical bore, two-lobe bore, three-lobe bore, four-lobe bore, or radial tilting pad

Options:

Electric insulation, lubrication circulation system, hydrostatic jacking

Accessories:

Temperature monitoring with PT100, prepped for vibration/speed sensors

Technical data

Design: EF bearing

Construction:

Finned side flange-mounted bearing acc. to DIN 31693 / ISO 11687-2

Size:

9 … 28, for shafts Ø 80 … 355 mm

35 … 45, for shafts Ø 300 … 560 mm (600 mm)

Lubrication:

Self-lubricating (loose oil ring, fixed oil ring) or external lubrication

Cooling system:

Natural cooling, water cooling, or external cooling

Bore design:

Various bore designs as required, e.g. cylindrical bore, two-lobe bore, four-lobe bore, or radial tilting pad

Options:

Electric insulation, lubrication circulation system, hydrostatic jacking

Accessories:

Temperature monitoring with PT100, prepped for vibration/speed sensors

Technical data

Design: EG bearing

Construction:

Unfinned pedestal bearing acc. to DIN 31690 / ISO 11687-1

Size:

18 … 28, for shafts Ø 160 … 355 mm

35 … 112, for shafts Ø 300 … 1,250 mm

Design: ER bearing

Construction:

Finned pedestal bearing acc. to DIN 31690 / ISO 11687-1

Size:

9 … 28, for shafts Ø 55 … 355 mm

35 … 45, for shafts Ø 300 … 560 mm

Lubrication:

Self-lubricating (loose oil ring, fixed oil ring) or external lubrication

Cooling system:

Natural cooling, water cooling, or external cooling

Bore design:

Various bore designs as required, e.g. cylindrical bore, two-lobe bore, four-lobe bore, or radial tilting pad

Options:

Electric insulation, lubricant circulation system, hydrostatic jacking

Accessories:

Temperature monitoring with PT100, prepped for vibration/speed sensor

Size

Types of locating bearings (Drive End): E…B, E…K, E…E

Type of non-locating bearings (Non-Drive End): E…Q

As an TECO Authorized Distributor, we can supply RENK slide bearings, RENK bearing bush, oil seal and oil ring etc. made in Germany via TECO Plants, No matter what brands of motors you use (including but not limited to: TECO, ABB, Siemens, WEG and Marathon), as long as RENK bearings are equipped on the motors, we could provide related services accordingly.

Our Advantages:

- 100% regular goods channel. RENK slide bearings and bearing SHELL will be purchased via TECO Motors Plant.

- 100% matched with original motors. As a high-voltage motor distributor over 10 years, we can make sure RENK bearings, RENK bearing bushes can match with original motors completely and correctly.

- We also provide other services like maintenance and replacement of components to make your work more efficient and easier.